With the ongoing technological revolution of mobile energy storage, high energy lithium-ion batteries have seen an upsurge in demand. The energy density of current, commercial lithium-ion batteries is significantly limited by the low specific capacity of cathode materials, which is less than half that of the battery’s graphite anodes.

Lithium-rich layered oxides are among the leading cathode candidates for high energy lithium-ion batteries due to their high specific capacities. However, the commercial application of lithium-rich layered cathode materials is significantly hindered by severe voltage decay and capacity loss during cycling.

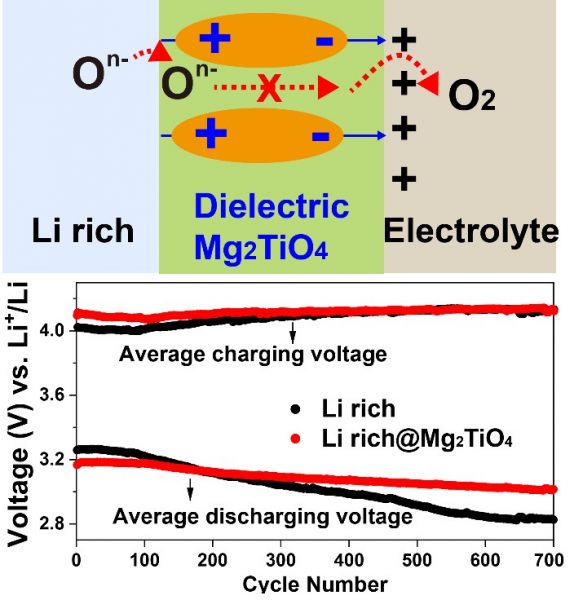

In a recent paper published in Advanced Materials, Professor Xiaodong Chen and colleagues have looked at the continuous oxygen loss from lithium-rich cathode materials, which is the root cause of the lower capacity of these materials.

The group designed a dielectric Mg2TiO4 coating to inhibit oxygen loss from the cathode. Due to the high oxygen-affinity elements of Mg and Ti the coating not only stabilizes the surface oxygen of lithium-rich materials, but the dielectric polarization of the coating effectively restricts the outward migration of oxygen anions towards the surface.

This work provides a new design principle to stabilize anionic reaction for high-energy-density electrode materials for next-generation rechargeable batteries.

“This work sheds light on a powerful avenue for unlocking the current challenges of high-energy energy storage devices via interdisciplinary problem solving,” said Chen.

Reference: W. Zhang, et al. ‘Dielectric Polarization in Inverse Spinel‐Structured Mg2TiO4 Coating to Suppress Oxygen Evolution of Li‐Rich Cathode Materials.’ Advanced Materials (2020). DOI: 10.1002/adma.202000496