Graphene holds promise in a wide range of industries, including the energy, medical, aviation, and electronic sectors, due to its unique electrical, mechanical, and optical properties. Understanding the processes that drive separation of graphite into single graphene sheets is crucial for large-scale application.

In a communication in Advanced Materials, Prof. Peter Coveney and co-workers from University College London elucidate the process that drives the exfoliation of graphite into graphene sheets by using molecular dynamic simulations to accurately simulate graphene behavior.

Prof. Peter Coveney: “Graphene in a certain sense has been known for as long as we have understood the structure of graphite, since graphite is just many stacks of individual sheets of graphene, and the problem has always been to isolate the individual sheets.”

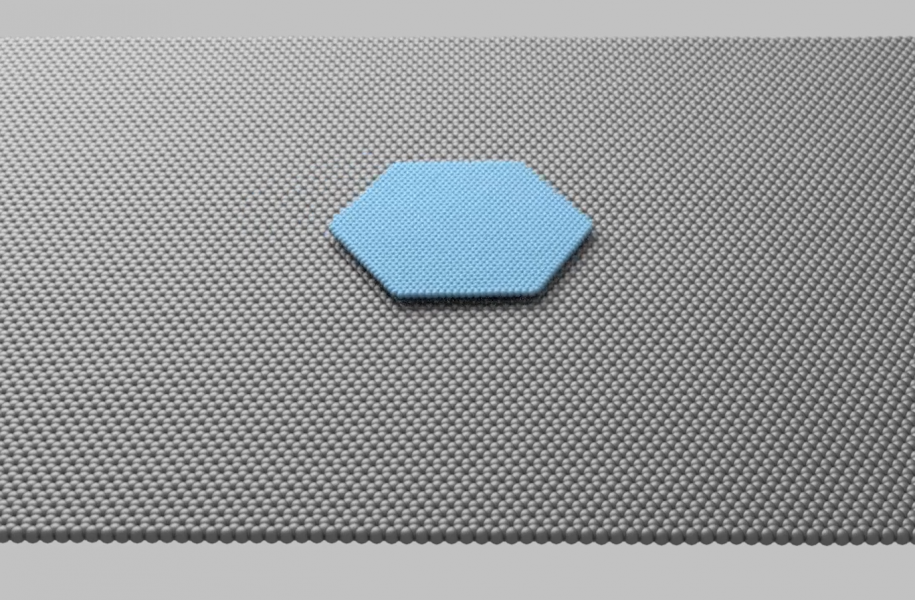

Robert Sinclair: “Using molecular dynamics, we have developed a new forcefield that allows us to look at graphene sliding on a graphite substrate. We see that the friction that the graphene displays is extremely low, almost like a puck in air hockey.”

This new forcefield, termed GraFF, recreates the energy barrier that graphene flakes experience when sliding over graphene, and allows the superlubric behavior of graphene to be revealed.

Prof. Peter Coveney: “Graphite is very slippery, because the sheets slide easily over each other in a lateral sense, but if you try to pull them apart vertically they simply don’t want to come apart.”

Two exfoliation mechanisms were investigated, and the work required to exfoliate graphene layers was shown to be 40% lower for the peeling mechanism than the shearing mechanism.

Further computations were performed, and higher temperatures were shown to increase surface undulation, impeding the sliding of the graphene flake across the surface.

To find out more about this computational study of the frictional properties exhibited by graphene, please visit the Advanced Materials homepage.