Researchers from the University of Georgia, Princeton University and Oxford University have described a simple controllable set-up for drawing single-filament nanofibers from polymer solutions or melts using a rotating rod or a set of rods (round brush). This method can be used to produce 3D tissue scaffolds by winding nanofibers onto spools of different shapes and dimensions and depositing cells of interest at the same time.

The fiber drawing is conducted via a very simple spinning set-up. The new method, which the authors named “touch-spinning”, has excellent control over the fiber diameter and is compatible with all kinds of polymeric materials, polymer melts, and solutions, polymer composite materials, and biopolymers.

The fiber drawing is conducted via a very simple spinning set-up. The new method, which the authors named “touch-spinning”, has excellent control over the fiber diameter and is compatible with all kinds of polymeric materials, polymer melts, and solutions, polymer composite materials, and biopolymers.

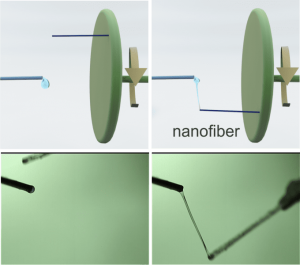

A glass rod is glued to a rotating stage, whose diameter can be chosen over a wide range of a few centimeters to more than 1 m. A polymer solution is supplied, for example, from a needle of a syringe pump that faces the glass rod. The distance between the droplet of polymer solution and the tip of the glass rod is adjusted so that the glass rod contacts the polymer droplet as it rotates.

Following the initial “touch”, the polymer droplet forms a liquid bridge. As the stage rotates the bridge stretches and fiber length increases, with the diameter decreasing due to mass conservation. It was shown that the diameter of the fiber can be precisely controlled down to 40 nm by the speed of the stage rotation.

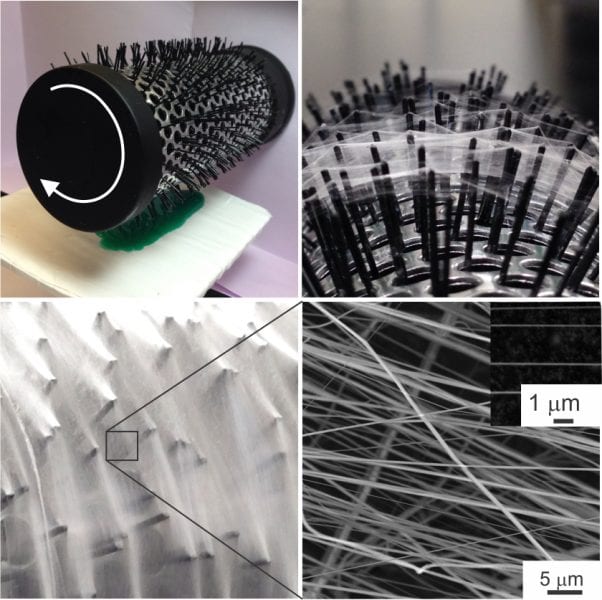

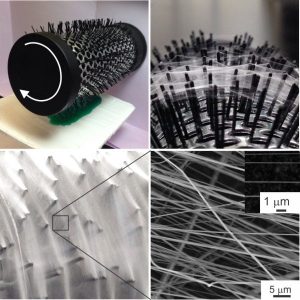

The method can b e easily scaled-up by using a round hairbrush composed of 600 filaments.

e easily scaled-up by using a round hairbrush composed of 600 filaments.

When the rotating brush touches the surface of a polymer solution, the brush filaments draw many fibers simultaneously producing hundred kilometers of fibers in minutes.

The drawn fibers are uniform since the fiber diameter depends on only two parameters: polymer concentration and speed of drawing.

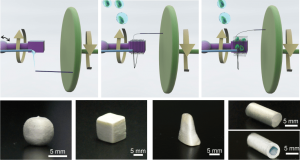

One important aspect of the method is the drawing of single filament fibers. These single filament fibers can be easily wound onto spools of different shapes and dimensions so that well aligned 1D, orthogonal, or randomly oriented fiber meshes with a well-controlled average mesh size can be fabricated.

Owing to simplicity of the method, the set-up can be used in any biomedical lab and facility. For example, a customized scaffold by size, dimensions and other morphological characteristics can be fabricated using donor biomaterials.

The spinning set-up is so simple and inexpensive that it can be fabricated as a single-use device for bioengineering labs and health care providers. Other examples include, but are not limited to, filtration technologies and fibrous non-wettable coatings of textiles.