Traditional polymerizations such as free-radical polymerizations, ionic polymerizations, coordination polymerizations of alkenes, as well as condensation polymerizations and ring-opening polymerizations, are generally used for the preparation of rubbers, plastics, and fibers.

Traditional polymerizations such as free-radical polymerizations, ionic polymerizations, coordination polymerizations of alkenes, as well as condensation polymerizations and ring-opening polymerizations, are generally used for the preparation of rubbers, plastics, and fibers.

Through polymerizations of alkynes, functional polymers with unsaturated structures and optoelectronic properties can be obtained, which may find applications in light-emitting diodes, solar cells, and sensors.

However, the efficiency and convenience of alkyne polymerization remain to be improved to realize environmental friendly and scalable polymerization.

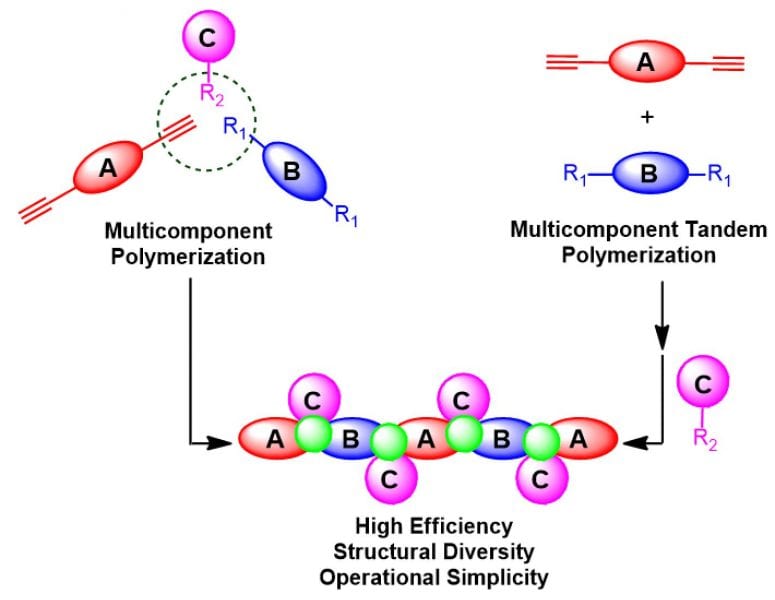

Inspired by multicomponent reactions, which can efficiently deliver products with structural complexity and diversity, together with the rich chemistry and high reactivity of alkynes, Rongrong Hu and co-workers at South China University of Technology have investigated alkyne-based multicomponent polymerization (MCP) to afford polymer product from three or more kinds of monomers in a one-pot procedure.

The polymerization enjoys advantages such as high efficiency, operational simplicity, high atom-economy, mild reaction condition, and structural diversity of products.

To meet the requirements of green chemistry, they have explored metal-free or catalyst-free MCPs of alkynes, aiming to synthesize polymers with well-defined structures efficiently.

Furthermore, they adopted a “one-pot, two-step, three-component” tandem strategy in the alkyne polymerizations, allowing the reactive intermediates from the first step to undergo next reaction in situ.

Such multicomponent tandem polymerizations avoid the isolation and purification of intermediates, increase the synthetic efficiency and reduce the cost.

It is anticipated that through the exploration of MCPs based on alkynes, a convenient and efficient approach can be provided for the synthesis of opto-electronic active polymers, and the production of a large variety of polymer materials with new structures.