Hybrid materials contain two different components, usually an organic and an inorganic phase, interacting at a nano-sc ale. This fine interaction forms materials with unique properties. For example, the organic phase provides flexibility while the inorganic phase gives strength. Therefore, hybrid materials are applied to various fields from electronics to biomaterials.

ale. This fine interaction forms materials with unique properties. For example, the organic phase provides flexibility while the inorganic phase gives strength. Therefore, hybrid materials are applied to various fields from electronics to biomaterials.

It is crucial to systematically design the properties of the hybrids to make bespoke materials for different applications. The hybrid properties are affected by the ratio of organic to inorganic components, as well as the number and position of the links between the two. Introducing well-defined polymers with precise composition, 3-D architecture, and size allows fabricating more advance hybrid materials with tailor-able properties.

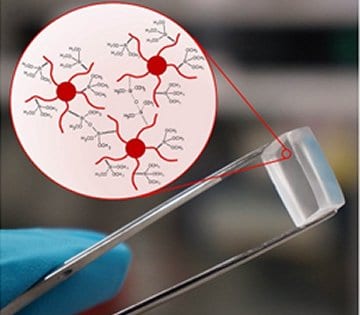

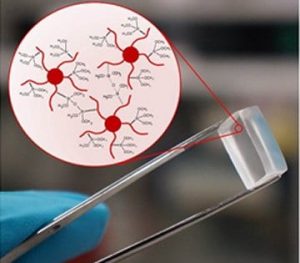

Researchers from the Department of Materials at Imperial College London have synthesized functional well-defined star polymers that were then linked to fabricate hybrids. Specifically, the star polymers contained alkoxysilane groups which made possible to form a silica, or glass, network between the polymers and thus producing a novel hybrid. This process was carried out in a one-pot method using Group Transfer Polymerization, a facile and scaled up living polymerization technique. This polymerization technique not only allows modifying polymers to have different sizes, compositions, and 3-D architectures, but also positioning of the alkoxysilane groups. Therefore, the researchers envision that this methodology can be used to produce more advance hybrid materials in large scales.