Facile Preparation of High-Performance Elastically Stretchable Interconnects

Stretchable electronics represents a new step closer to biomimicry of skins and muscles, which, unlike flexible electronics, can remain fully functional under strain. An ultimate goal of stretchable electronics is to integrate rigid electronics into soft biological electronic systems, such as the neural interface.

While such a blueprint certainly sounds appealing, many technical challenges are yet to be resolved, two critical of which are the poor adhesion of conductive films on elastomeric substrates and the difficult patterning with standard photolithography. Now, Patrick Görrn and co-workers at University of Wuppertal (Wuppertal, Germany) report a facile two-step approach to high-performance stretchable interconnects by addressing both issues at the same time.

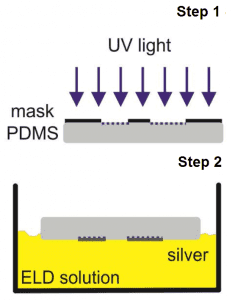

In the first step, a polydimethylsiloxane (PDMS) foil substrate is treated with UV light through a photolithography mask. The purpose of UV irradiation is to define the electrode deposition areas while increasing the film adhesion, as found out by the authors earlier when they studied how adhesion can influence the morphology of silver nanoparticles that were deposited in a vacuum process. The second step involves electroless deposition (ELD) of pattern films using a standard ELD solution consisting of diamine silver(I) ion and glucose. As UV light can increase the degrees of both cross-linking and oxidation of PDMS, the surface of PDMS becomes more hydrophilic, enabling site-selective ELD with enhanced adhesion.

Integrating “rigid island” on soft substrates

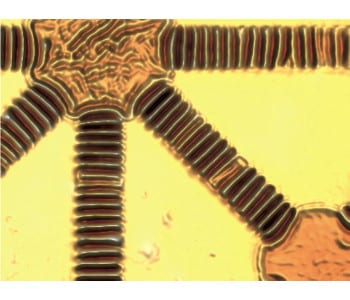

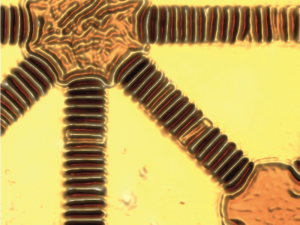

The stretchable interconnects prepared using this method feature wrinkled silver lines that can withstand repeated large strain, only showing minimal fluctuations in resistance. In addition to one-dimensional (1D) stretchable lines, the researchers also demonstrate 2D stretchable wrinkle networks that allows for the integration of rigid electronics using the so-called “rigid island” approach. Since the crossing points of stretchable lines are not influenced by strain, rigid integrated circuits can be placed accordingly as “islands”, connected to soft substrates by stretchable interconnects.

These findings provide a fast and cost-efficient approach to stretchable interconnects without the need for organic solvents or vacuum processing. Besides prospective applications in bioelectronics, it is readily adaptable for “large area optoelectronics like stretchable solar cells or displays”, one of the directions the authors are currently working on. In an effort to further reduce the spatial resolution of this method, they “will also validate if the patterning approach in combination with electron beam exposure can enable submicron size stretchable features on PDMS”. However, to achieve fully seamless bionic interfaces, silver-based interconnects are still not ideal due to poor biocompatibility. In this regard, while having already “removed a couple of toxic chemicals in our ELD solution”, the authors now focus on developing “a process for realizing gold interconnects that are fully biocompatible”.