by Ying Liu (North Carolina State University)

Silk proteins, which can be created by Bombyx mori, spiders, moths and numerous insects, have been widely studied in many different forms such as hydrogels, sponges, composites, thin films, microspheres, and fibers due to their impressive mechanical properties, soft texture, biodegradation, and biocompatibility. Fibers are one of those popular forms and have been widely applied in such as textile industry, biomedical applications like sutures and would dressing, and tissue engineering scaffolds.

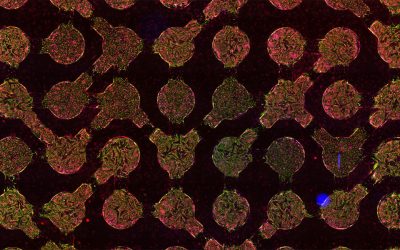

Electrospinning is one common technique for making these silk fibers, which uses electric force to draw charged threads of polymer solutions or melts to the polymer fibers in desired diameters (usually in nanometers). For example, the silk fibrous mats are used as artificial scaffolds for tissue engineering. The electrospun silk fibrous mats have demonstrated good growth and proliferation of various cell lines like normal human keratinocytes, fibroblasts, and osteoblasts. Moreover, the protein structures can be controlled by the type of solvents for spinning.

Electrospinning is one common technique for making these silk fibers, which uses electric force to draw charged threads of polymer solutions or melts to the polymer fibers in desired diameters (usually in nanometers). For example, the silk fibrous mats are used as artificial scaffolds for tissue engineering. The electrospun silk fibrous mats have demonstrated good growth and proliferation of various cell lines like normal human keratinocytes, fibroblasts, and osteoblasts. Moreover, the protein structures can be controlled by the type of solvents for spinning.

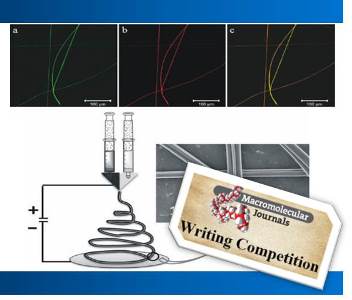

One challenge is to produce hybrid fibers, a combination of silk proteins with other synthetic or natural, biodegradable or biocompatible polymers, so that silk fibers are more feasible or highly tunable. There are four main strategies to make hybrid fibers. First, silk is blended with other biodegradable and biocompatible polymers. Second, two polymers are sequentially spun to form layered structures. Third, core-shell fibers are made. Last, side-by-side morphology so that two polymers at different sides of the same fiber. The last strategy (side-by-side morphology) is advantageous over other three since both sides of fibers are available for post-spinning modification. Moreover, two surfaces in one fiber with different surface chemistry offers the opportunity as compatibilizers for co-culture of different cells and drug-releases, and tuning degradability profiles on two sides of the fiber.

The research group, from University of Bayreuth in Germany, has demonstrated the combination of bio-based poly(L-lactide) (PLLA) and Bombyx mori silk fibroin in a single fiber using this advantageous side-by-side strategy. The two sides of two-in-one fibers retained their own structure and mechanical properties before and after annealing process without interferencing each other. It will be interesting to follow the research by using these fibers with side-by-side morphology to generate two-side surface chemistry for biodegradation studies, cell culture, scaffold, and drug-release application in the future.

We would like to thank all participants in the Macromolecular Journals Writing Competition.

We would like to thank all participants in the Macromolecular Journals Writing Competition.

The best contributions are now featured on MaterialsViews and will go into the draw for the iPad mini. The winner will be drawn at the Macromolecular Colloquium, February 2016 in Freiburg and will be informed by email.

We hope you enjoy reading the news articles from our young talents.

Enjoy a different perspective on this article by clicking here.