Two-dimensional (2D) materials are atomically thin, with thicknesses reduced to a single or a few layers of atoms. Graphene is one of the most famous examples, where its structure has imparted it with some interesting properties, such as being tough, flexible, and light.

Because of the exceptional nature of 2D materials, they have found application in a variety of fields, from electronics to medicine. However, they are still difficult to produce at scale, making their commercialization difficult. In particular, once the 2D sheet is made, it is difficult to transfer it without breaking it.

Using ice to transfer 2D materials

In a study published in Advanced Materials by researchers at the City University of Hong Kong and their collaborators, a new method involving the adhesive capabilities of ice as a means of transferring 2D materials from one medium to another was tested.

“We propose a contamination-free method for transferring 2D materials to and from different substrates,” explained Thuc Hue Ly, assistant professor at the Chemistry Department of City University of Hong Kong. “The conventional transfer method involves using a polymer supporting layer, which was first developed in 2009 for transferring graphene and other 2D materials [such as transition metal dichalcogenides (TMDs)].

“However, it is difficult, if not impossible, to completely remove the polymer residues, leading to degradation in the quality of 2D materials. In contrast, our ice-aided transfer/stamping method fundamentally solves the contamination issue that has perplexed the scientific community for over a decade.”

Other researchers had previously tried using liquid water, but it did not give good results because it was too dynamic. Ly and her team therefore decided to use “solid water” instead. “Ice exhibits strong hydrogen bonding, which enhances the adhesion between the TMD sample and the ice, ensuring successful detachment of the sample from the surface it was made on,” explained Ly.

The adhesive properties of ice are well known to scientists — as well as any of us who have ever had our tongues stuck to a Popsicle — but its application to 2D materials has never been explored until now.

But the road was not easy, and the group had to deal with several critical issues before it worked. “We had to find a way to make a flat ice surface for the transfer,” said Ly.

Controlling ice

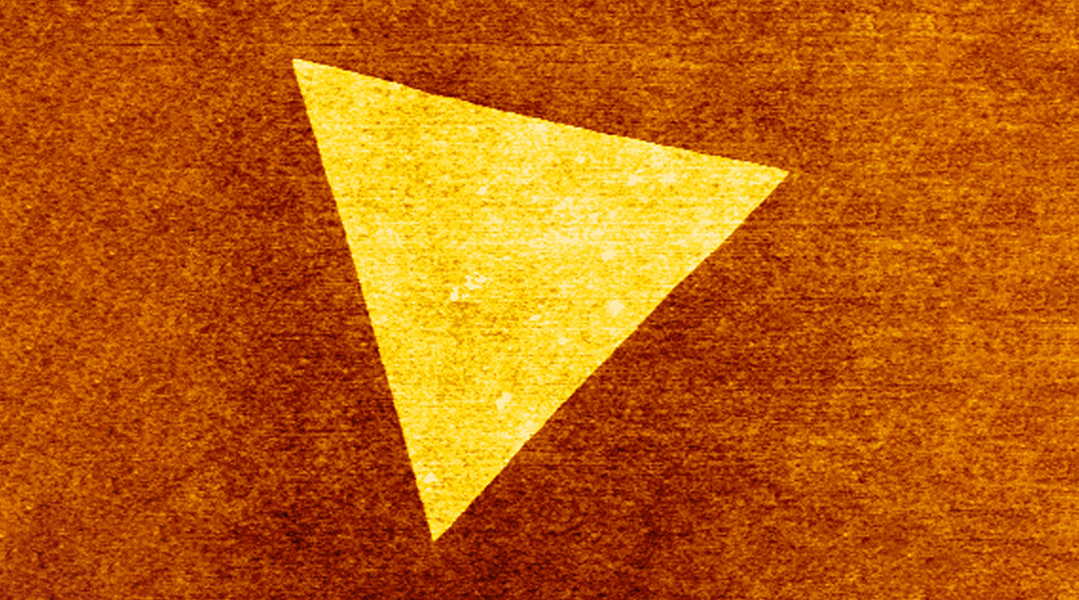

Frozen surfaces are often rough, making them unsuitable for transferring a thin 2D material because when a supporting surface is not homogeneous, it tends to trap other materials too. 2D materials are so thin that even a tiny impurity could ruin the properties of the whole layer.

The team say they used a “flipped” substrate to make a sandwich-like structure to produce the ultra-flat ice surfaces for 2D material transfer.

“The first author of this work, Haijun Liu, found the strong adhesion of ice to 2D materials, and the level of adhesion can be controlled based on environmental temperature and the nature of the surface, such as its ‘hydrophilicity’ or the ability to attract or interact with water. These results have been confirmed by the first principles theoretical calculations of Professor Qingming Deng from Huaiyin Normal University,” said Ly.

The study also showed that 2D materials transferred through ice had better electrical performance compared with those transferred by conventional methods. This technique could also help increase the breadth of application, especially in the fields of semiconductors or biomedicine, where the absence of contaminants is critical.

“Taking advantage of the ice transfer technique can effectively reduce the introduction of impurities into 2D materials, thereby improving the biological compatibility of an implanted device and reducing the detriment of contaminants to biological samples,” concluded Ly.

Reference: Jiong Zhao, Qingming Deng, Thuc Hue Ly, et al., Controlled Adhesion of Ice—Toward Ultraclean 2D Materials, Advanced Materials (2023). DOI: 10.1002/adma.202210503