Hybrid lead halide perovskites (ABX3, with A = cation(s), B = Pb and X = halide(s)) have in the recent years emerged as promising absorber materials for modern photovoltaics (PV). Since the first report on perovskite solar cells (PSCs), power conversion efficiency (PCE) of PSCs has quickly grown, with a record PCE value of >22% recently achieved with devices based on a mixed-cation (A)/mixed-halide (X) perovskite. Tuning the composition of the absorber material is thus key for targeting a maximized efficiency.

Mixed hybrid lead halide perovskites are typically prepared via multi-stage solution-processing techniques, this in spite of the intrinsic drawbacks of solution-based methods (i.e., lab-scale only devices can be fabricated and toxic solvents are typically required).

Ideal methods are instead vapor-based techniques, a mature technology that is already well-established in the coating and semiconductor industry. A major challenge in vapor-processing mixed hybrid lead halide perovskites is achieving the simultaneous vacuum deposition of the perovskite single components from multiple precursor sources. This clearly requires a high level of control over precursors’ deposition (rate) during perovskite film formation.

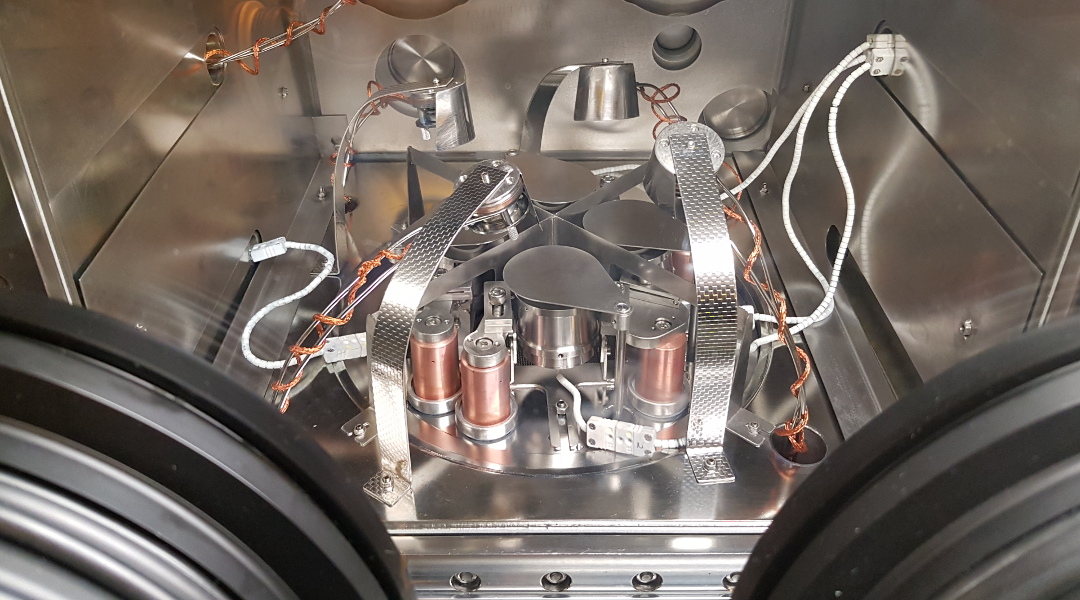

In a recent work, Dr. Bolink and co-workers reported on an innovative multiple-source thermal vacuum deposition technology for growing mixed-cation/mixed-halide perovskite layers. Among all the possible composition combinations, a three-cation/two-anion perovskite (Cs0.5FA0.4MA0.1Pb(I0.83Br0.17)3) was shown to yield the most efficient and stable PSC.

The reported results extend the use of vapor-deposition technology to mixed hybrid perovskite systems, and offer a convenient approach to tune thickness and composition of the absorber layer. Even more, the authors foresee that vapor-deposition techniques are a processing method that can be adapted to yield more complex absorber systems (e.g., complementary wide/narrow band-gap perovskites) and devices, which will ultimately break the currently established record efficiency.