Hydrogel-based contact lenses are used by approximately 150 million people worldwide to correct vision and for cosmetic purposes. Their ubiquitous nature, biocompatibility, and flexibility make them attractive candidates for minimally invasive diagnostic devices for the continuous monitoring of ocular disease markers.

Over the last decade, electrochemical sensors have been integrated into contact lenses to measure markers such as glucose concentration for diabetes management and intraocular pressure for the clinical management of glaucoma. Even more recently, electronic contact lenses have been developed to wirelessly measure glucose concentration in tear fluid and intraocular pressure simultaneously, by electrochemical reactions. Unfortunately, most electronic contact lenses are complicated to fabricate, are unreliable due to the electrochemical signal drift caused by blinking, and can obstruct the vision of a patient.

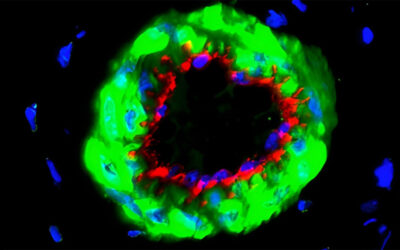

Dr. Ali K. Yetisen and co-workers have developed a method to fabricate microfluidic contact lenses by combining laser ablation patterning and microlithography, as presented in their study published in Small. Their method leads to a microfluidic contact lens consisting of embedded microconcavities connected to microchannels with controlled depth and diameter. The system is tested through a variety of parameters, including flow testing of artificial tears and the functionalization of the channels with fluorophores, to demonstrate optical excitation and emission within the visible spectrum. Furthermore, the lens is transparent and breathable, which are important factors for the comfort of the patient.

The fabricated microfluidic contact lens offers the potential for multiple biomarkers sensing through detection in the tear fluid, and sequential and controlled drug release for the diagnosis and treatment of eye disease.