Nowadays, computers and electronics are incorporated into almost all processes of our daily lives, from reading a news article on a smartphone, to tracking daily activity on a smartwatch, and improving hearing through use of a hearing aid. These wearable devices can have a variety of functions, such as measuring external stimuli response and monitoring physiological and biomechanical signals of the body, making them increasingly desirable as components integrated into personal life.

Personal thermal management (PTM) devices provide the potential to adjust body temperature to a thermally safe and comfortable state. Essential elements of a successful PTM device are that they are lightweight, flexible, breathable and as safe as normal clothing for human skin. However, most current PTM systems are made from types of conductive materials, such as Ag nanowires, carbon nanotube and graphene, and feature elements which allow for the insulation or release of human body infrared (IR) radiation, providing a heating or cooling effect respectively. The greatest limitations of these materials is that they do not allow for warming and cooling within one textile and the antioxidation status of metallic nanowires deteriorates with decreased dimension as a result of high surface-area.

To remedy this, Dr. Yang Guo and colleagues use the blade-coating approach to prepare large-area, macroscopic assembled, free-standing and chemically stable graphene papers (GPs) with adjustable thickness in their prospective PTM device, recently published in Small. GPs have been used in the past in a variety of contexts, such as thermal management for high-power electronics, energy storage devices and planar lighting, but have been rarely used previously in PTM despite their superior chemical and mechanical stability, high thermal conductivity and low electrical resistance.

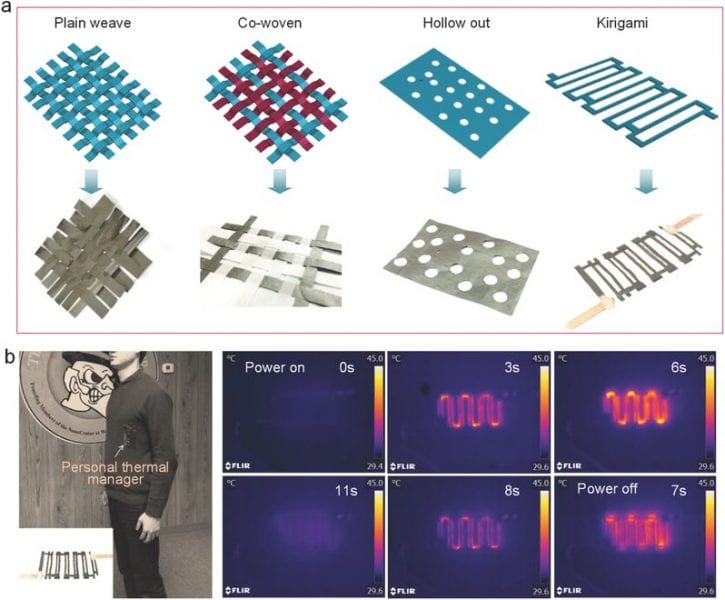

Wearable PTM devices. a) PTM device designs. b) Demonstration of a wearable PTM device in the kirigami structure in an applied voltage of 3.2 V. Both heating-up (power on) and cooling-down (power off) processes are shown.

Their GP allows for joule heating to 42 °C using a low supply voltage of ≈ 3.2 V. It also provides passive cooling via thermal transmission from the body to the environment within 7 s, which is faster compared with that of normal cotton fiber. Finally, it is highly durable, can be fabricated into a variety of designs (see Figure), and can withstand over 500 bending cycles and wash times over 1500 min, suggesting its great potential in wearable PTM.

The relevance of their GP for PTM is that they offer a simple, low-cost approach to ensure safe and comfortable heating and cooling in a variety of complex and volatile environments without compromising breathability.