Bubbles of CO2 are a critical component of beer making and consumption.

The annual global carbon dioxide (CO2) footprint for the cradle-to-grave production of nearly 200 billion liters of beer per year accounts for around 5% of global greenhouse gas emissions. Even disregarding the proportion associated with production, this favorite alcoholic beverage contains roughly 1.2g of CO2 per liter, contributing around 100,000 tonnes of greenhouse gases into the atmosphere annually from escaped bubbles alone.

While these 100,000 tonnes only make up 0.01% of yearly greenhouse gas emissions, its presence in beer makes an enormous difference. The rate bubbles are produced and rise to a foamy head in a freshly poured glass, coupled with the gas’ signature tang, are pivotal to deciding our favorite brews.

It can be seen why understanding the thermodynamics and kinetics of bubble nucleation and growth is vital to both producers and consumers of the world’s most popular alcoholic beverage.

A recent report theoretically and experimentally determined the critical radius of heterogeneous nucleation sites on glass (1-10 mm), the concentration of dissolved CO2 (2-5 g/L), and the conditions at which bubble formation becomes thermodynamically possible for a poured 250 mL glass of commercial lager beer at 6°C under standard tasting conditions. As well, the number of CO2 bubbles produced at the nucleation sites throughout the outgassing process (105-106) was also determined.

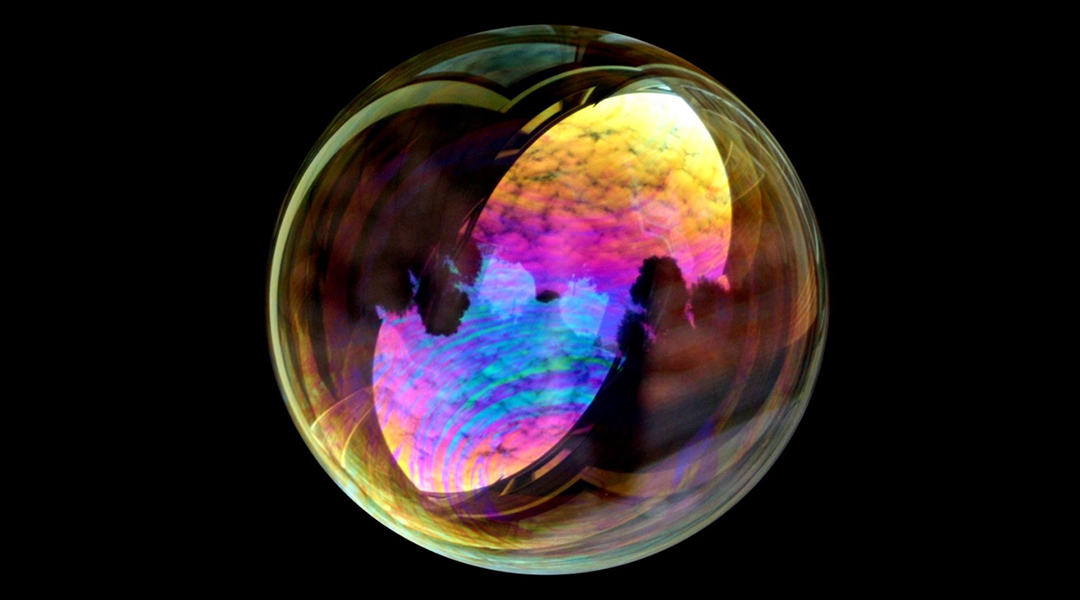

High-speed photography was used to image the ascending beer bubble dynamics responsible for foam formation at the drink’s surface. It was found that the process involved three main steps: initiation by bubble cavitation, diffusion, and buoyancy-driven growth. Additionally, the quantity and quality of the froth was determined to be dependent on the properties of the liquid and glass in conjunction with the total number of bubbles formed from the dissolved CO2.

Despite its importance, it is not the bubbles in your beer which holds heavy environmental impact. The grain-to-glass procedure is inundated with high-emitting processes. From production and transportation of raw materials and packaging to resource consumption in the brewery, transportation, refrigeration, and waste recycling, the issue of sustainability must be addressed lest we ourselves no longer able to share shore-side stories while cracking a few cold ones with friends.

So, the next time you toast with a glass of beer, be mindful of what it took to get that drink to your hand.

Written by: Geoffrey Ozin and Jessica Ye

Reference: Gérard Liger-Belair and Clara Cilindre, How Many CO2 Bubbles in a Glass of Beer? ACS Omega, (2021). DOI: 10.1021/acsomega.1c00256