The wind energy market is one of the most promising markets of renewable energies. It is expected that offshore wind energy will deliver the biggest part of renewable electricity in the near future. The increasing number of offshore wind turbines cannot only be located close to the coast. Thus, installation areas and estimated water depths will be significantly different to today’s offshore wind parks.

near future. The increasing number of offshore wind turbines cannot only be located close to the coast. Thus, installation areas and estimated water depths will be significantly different to today’s offshore wind parks.

Offshore wind turbines have to withstand very high dynamic loads caused by wind, waves and operation. Additionally, offshore turbines are exposed to highly corrosive environmental conditions. Therefore, fatigue resistance becomes relevant for providing secure service time as well as economic design and to minimize maintenance costs.

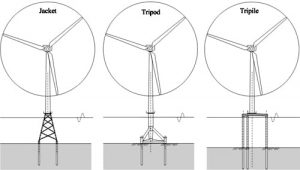

In a recent publication, P. Schaumann and co-workers give an overview of typical types of offshore support structures and describe the character of dynamic loads and fatigue resistances of specific constructional details.

In a recent publication, P. Schaumann and co-workers give an overview of typical types of offshore support structures and describe the character of dynamic loads and fatigue resistances of specific constructional details.

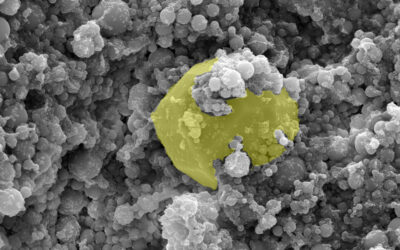

The support structure of an offshore wind turbine consists of the tower and the substructure. The substructure includes all structural components below the tower together with the foundation. The connection between substructure and tower of offshore wind turbine are commonly realized by tube-to-tube-connections which are filled with high performance grout, the so called grouted joints.

Besides these grouted joints, Schaumann, et al. give special consideration to welded joints. In order to extend experimental investigations of welded joints a testing device was developed operating by alternating current magnets and using resonance amplification. Until now, the experiments are continued.

Thumbnail Image: Matt Banks / FreeDigitalPhotos.net