After several years of research thyssenkrupp Steel Europe has started operation of the world’s first automated sinter test facility. In the future it should also help to reduce emissions from the production sinter plant.

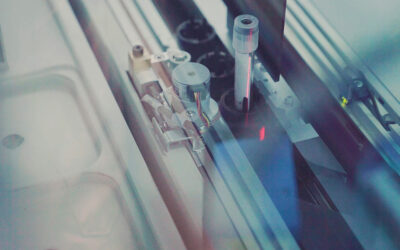

A new sinter test facility optimizes the composition for steelmaking. Credit: thyssenkrupp Steel Europe

“Using the facility we will be able to react quickly to global changes in ore grades and offset differences flexibly. Thanks to full digitization of the test process we will be able to keep an eye not only on precise quality indicators but also the emissions contents of our charge materials,” says Dr. Urban Janhsen, head of the Technology Ore and Iron team.

During sintering, fine grains of iron ore are mixed with other materials, heated intensely and baked together into lumps through fusing of the grain edges. The lump shape of the so-called sinter cake is necessary for the production of pig iron in the blast furnace. For the daily mass production of sinter the test facility will make it possible within a few hours to predict exactly the optimum mix of charge materials. From the weighing of samples before testing to examining the finished sinter, a robot will handle all handling and transport steps, as the company told.

Another innovation is dust analysis during the entire test process, designed to facilitate reductions in emissions. Dust emissions are measured by laser and can be assessed as representative samples. Thanks to the automated workflow, low-dust charge materials can be identified and the optimum charge mix determined.