With the most recent order to MAN Diesel & Turbo, the company already won the third sub-project contributing to this multinational experimental set-up. The 13 so-called Port Stubs, fabricated for the Italian company Walter Tosto, are to be installed in ITER’s vacuum vessel. This vessel will house the fusion reactions and act as a first safety containment barrier. The Port Stubs are the connecting element between the vacuum vessel and the ports. The latter provide access for remote handling operations and other installations as diagnostics, heating, and vacuum systems.

“We are helping to bring the source of the sun’s energy down to earth – our experts participate in the construction of a fusion reactor which may soon demonstrate power can be generated in the same way the sun does it”, says Dr. Uwe Lauber, CEO of MAN Diesel & Turbo. “MAN continues to contribute to the development of leading-edge technologies with its high-tech equipment and enormous technical knowledge.”

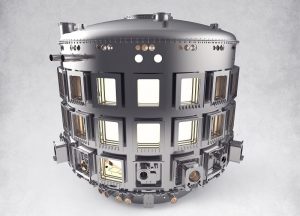

The ITER’s vacuum vessel will house the fusion reactions and act as a first safety containment barrier. Source: MAN Diesel & Turbo

The ITER project is funded and run by seven member entities: Japan, the European Union, the United States, Russia, China, South Korea and India. In southern France, 35 nations are collaborating to build the world’s largest tokamak – a magnetic fusion device designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy based on the same principle that powers our sun and stars.

The first ITER order to MAN was booked in 2012. It encompasses the delivery of 18 so-called Upper Ports to Russian JSC “NIIEFA”, D.V. Efremov Institute of Electrophysical Apparatus as sub-contractor. More than 1000 tons of stainless steel is currently being processed by MAN in Deggendorf in order to deliver the Upper Ports starting mid-2017.

MAN received the second ITER order from Indian multinational conglomerate Larsen & Toubro, which is manufacturing the critical Cryostat at Hazira, India. The order comprises the assembly of the Cryostat. The largest stainless steel high-vacuum chamber ever built (16,000 m³) provides the high vacuum, ultra-cool environment for the vacuum vessel and the superconducting magnets. With this order, MAN was one of the first companies on the construction site in France, where works started in mid-2016.

MAN Diesel & Turbo in Deggendorf has a vast experience with demanding projects within the scope of large-scale fusion experiments. The company has already participated in the construction of the Wendelstein 7-x plant and supported the project for 15 years by supplying the internal and external vessel as well as the machinery foundation. Wendelstein 7-x commenced test operation and produced the first plasma in 2016 – scientists from the Max Planck Institute are now studying the basis for the energy supply of the future.